Since 1971, Magnatech has been manufacturing a wide range of systems for orbital tube and pipe welding, as well as for tube-to-tubesheet applications. These innovative products emphasize simplicity, reliability, and ease-of-use.

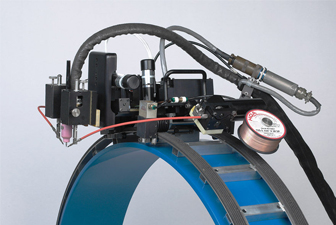

With this expertise Magnatech started developing pipeline welding systems around 15 years ago. Magnatech International BV introduced the system into the market with great success. The success of the Pipeliner II System is mainly based on reliability and easy-to-use-operation. A high deposition rate producing quality welds with close-to-0% repairs make it even more attractive.

The success is not only equipment related. Our customer approach is looking for partnership. “Partnership is sharing information, that’s what we do – sharing information and providing solutions”.

Today’s industry for pipeline welding is in great need of high qualified welders. The average age of a qualified welder worldwide is above 50, which means there will be a substantial shortage in the near future. This development and increasing quality constraints plea for use of automatic pipe welding systems as the consistent quality is produced by the equipment and not by high qualified welders anymore.

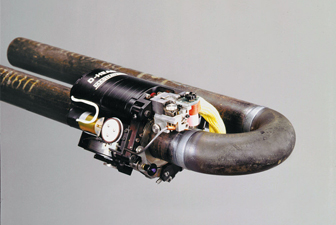

WELD HEADS FOR FUSION AND WIRE FEED GTAW TUBE-TO-TUBESHEET WELDING Magnatech Tubesheet Heads are designed to make tube-to-tube sheet welds with precision and repeatability. All models can be used for fusion welding. The models 424 and 425 provide for filler wire addition – an integral head-mounted feeder is standard.

Three models cover the size range of 10 to 140 mm (0.4 to 5.52″) OD. These weld heads improve productivity by increasing duty cycle, reducing repair rates and producing welds of consistent quality.